Optimizing Equipment Long Life: Buying Costs Undercarriage Parts Solutions

Optimizing Equipment Long Life: Buying Costs Undercarriage Parts Solutions

Blog Article

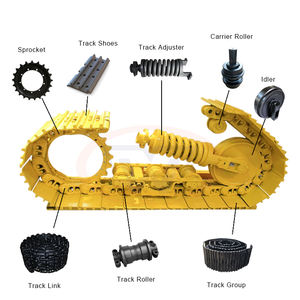

Discover Undercarriage Parts for Heavy Equipment

Understanding the ins and outs of undercarriage components is vital for the ideal efficiency and long life of hefty machinery. From track footwear to idlers, sprockets, and rollers, each part plays a vital role in the functionality of the tools. Delving into the specifics of these parts reveals a world of accuracy engineering and resilience that maintains hefty machinery operating at its optimal. Keep tuned as we discover the relevance of undercarriage parts and discover the upkeep practices that can boost the performance of these crucial components.

Relevance of Undercarriage Components

The undercarriage components of heavy equipment play an essential duty in guaranteeing the total efficiency and durability of the equipment. These parts, consisting of tracks, rollers, chains, sprockets, and idlers, develop the structure whereupon the equipment runs. A properly maintained undercarriage not just gives security and support to the hefty equipment but additionally contributes dramatically to its operational performance and efficiency.

Among the vital advantages of investing in premium undercarriage parts is the decrease of downtime and upkeep expenses. By making use of long lasting elements that can hold up against the roughness of heavy-duty applications, drivers can decrease the need for regular repairs and replacements, thus making best use of the machine's uptime and overall lifespan.

Furthermore, properly operating undercarriage components guarantee optimal weight circulation, ability to move, and grip, allowing the hefty equipment to operate efficiently also in difficult surfaces. This integrity is essential for industries such as mining, agriculture, and building, where devices performance straight influences task timelines and profitability. To conclude, the value of undercarriage parts can not be overstated in keeping the performance and longevity of heavy machinery.

Kinds Of Track Shoes

When considering the different types of track shoes for hefty equipment, it is vital to assess their layout and performance in regard to certain functional requirements. Track footwear are essential parts of the undercarriage system, providing grip, weight, and security circulation for hefty equipment such as excavators, excavators, and spider cranes.

The most common types of track shoes include:

** Grouser Shoes **: Featuring elevated steel bars (grousers) along the shoe's surface, these track footwear provide boosted traction in challenging terrains like mud, snow, and loosened gravel. undercarriage parts.

** Dual Grouser Shoes **: Similar to grouser shoes however with website link an added collection of grousers, these track footwear provide also higher grip and security, making them optimal for very harsh terrains.

** Triple Grouser Shoes **: With 3 collections of grousers, these track footwear give maximum grip and security, making them suitable for the most requiring conditions.

Choosing the right kind of track shoe is crucial for optimizing the performance and long life of hefty machinery while guaranteeing safety and effectiveness throughout procedures.

Function of Rollers and Idlers

Rollers and idlers play important duties in sustaining and directing the track footwear of heavy equipment throughout operation. Rollers are round elements that sustain the weight of the devices and ensure smooth activity along the surface. They aid disperse the equipment's weight uniformly, reducing wear on the track footwear and minimizing resonances. Idlers, on the various other hand, guide the track chain and help keep proper stress. By stopping too much slack or rigidity in the tracks, idlers add to the general security and performance of the machinery (undercarriage parts).

Additionally, rollers and idlers collaborate to keep the track shoes in placement, preventing them from slipping or hindering off throughout procedure. Properly working idlers and rollers are important for making certain the long life of the undercarriage system and making best use of the device's effectiveness. Normal upkeep and inspection of these parts are necessary to determine any kind of signs of wear or damage early, protecting against costly repair work and downtime in the future.

Function of Gears in Equipment

Upkeep Tips for Undercarriage Parts

Reliable upkeep of undercarriage components is important for guaranteeing the longevity and optimal efficiency of hefty equipment. Normal assessment of undercarriage parts such as track chains, rollers, idlers, sprockets, and track footwear is crucial to look here avoid pricey fixings and unexpected break downs. It is likewise vital to ensure correct track stress to protect against early wear on components.

Conclusion

In final thought, the undercarriage components of heavy equipment play a vital role in making certain the smooth functioning and long life of the equipment. Understanding the significance of track footwear, rollers, idlers, and sprockets, as well as applying proper upkeep practices, can greatly influence the overall efficiency and performance of the equipment (undercarriage parts). Regular examination and timely replacement of damaged parts are vital in taking full advantage of the life-span and efficiency of hefty machinery

Rollers and idlers play important roles in sustaining and directing the track shoes of hefty equipment during procedure.In hefty equipment, sprockets offer a critical feature in moving power from the engine to the tracks, making it possible for the devices to relocate effectively and efficiently. try this site These parts are attached to the axles or last drives of the machinery and job in combination with the tracks to push the tools forward or backwards. Routine examination of undercarriage components such as track chains, rollers, idlers, gears, and track footwear is crucial to stop expensive repairs and unexpected failures. Recognizing the significance of track shoes, rollers, idlers, and gears, as well as applying proper upkeep methods, can significantly impact the general performance and efficiency of the machinery.

Report this page